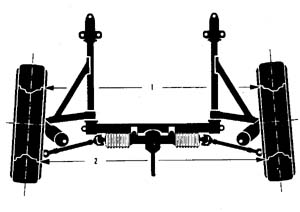

912 Toe-in AdjustmentWhen backing out of the driveway, I heard a rattle from the front suspension when the front wheels crossed over the last bump to the street. It was time to change the tie-rod and lower ball joints.In addition there was a bump steering problem where the wheel would tug in your hand when going over a bump at low speed. After changing the tie-rod ends, toe-in must be adjusted to bring the car back in alignment. Toe-In SpecificationFrom the factory manual: For later LWB cars:Toe-in each wheel 20 sec Toe-in each wheel 0 sec Adjusting Toe InTo adjust toe-in measure the distance between the front of the front tires and the back of the tires. See this article for a good way to adjust toe in.  Center the Steering WheelCenter the steering wheel on the steering column. This is done by turning the steering wheel to the locks in both directions and noting the angle of symmetrically located spokes. With the standard four spoke wheels, use the lower spokes. On my Momo three spoke wheel, I use the lower spoke. The wheel must be removed and replaced on the steering column, rotating by half the angle until it is the same final angle lock to lock. Now when the car is moving straight down the road, the steering wheel should be centered. But it won't be. To bring the steering wheel back to the center, the tie rods have to be adjusted. If the toe-in adjustment is correct, the tie rods can be rotated the same amount, maintaining the correct toe-in, and changing the relative position of the axles to the steering wheel. Trial and error works reasonably well. Guess at the final result, for instance by rotating each tie rod by one full turn. You will shorten one and lengthen the other. You can make the adjustment without jacking the car, gaining access to the tie rod behind the tire by turning the wheels as far a possible in each direction. Test drive the car. We just drove it around the block. Now that you know what a full turn has done to the centering of the steering wheel, extrapolate what must be done to make it correct and try that. Test drive again. If your guesses are good, you should be able to acceptably close on the third try. Don't forget to tighten the tie rod clamps after the last adjustment. Other Methods of Measuring Toe-InThere are a variety of methods the home mechanic can use to measure toe-in, several of which are field tested by the racing community. Open Wheeled CarsIf you can get good enough access to the front and rear of your tires, the following technique works. A special jig is made out of square tubing wth an 'L' shape at one end and a 'T' shape at the other. A scribe line, tread feature or molding line is picked on the tire that circumscribes the tread area of the tires. Each leg is the length of the radius of the tire. The 'L' shaped end has a slot cut in it that is placed precisely over the line. The 'T' shaped end has a piece of masking tape that is marked with the line. Two measurements are made one at the front and the other at the rear of the tire.

Links

Site Details.

Disclaimer.

Comments? Questions?

Dave Hillman

Content attribted to others remains their property. Otherwise the text and images are licensed under a Creative Commons License.

|