|

912 Adjust Valves

The valves were dangerously tight when the car was received. When

they are too loose they are noisy. The factory recommended settings

seem correct.

Valve Clearance

Intake: 0.10 mm (.004 in.) - center two valves

Exhaust: 0.15 mm (.006 in.) - outside valves

Tools

- Large crescent wrench to turn crank

- 13 mm box wrench

- Screw driver medium blade

- .003 - .008 in. feeler gauges

From the Owner's Manual

Excessive valve clearance results in a noisy engine and loss of power.

Insufficient clearance reduces performance and results in burned

valves: combustion flashback through an improperly closing valve can

cause a carburetor fire. Consequently, we recommend that the valves

be adjusted in a reputable shop. The valves should be adjusted only

when the engine is cold.

The easiest way to adjust the valves is to follow the cylinder

sequence 1-2-3-4 (see 912 ignition for

diagram of firing order) while turning the crankshaft

counter-clockwise (front to back, right to left). To adjust the valves

of any given cylinder, first bring the respective piston to its top

dead center (TDC) on compression stroke because this insures that both

valves of the particular cylinder are fully closed. When the

procedure is initiated with Cyl 1, turn crankshaft counter-clockwise

until both valves in Cyl 1 have closed and the "OT" mark on the

crankshaft pulley has lined up with the vertical mark on the crankcase

housing (distributor rotor pointing to a small notch on the ridge of

distributor housing).

- Remove the rocker box cover.

- Remove the distributor cap so you can see which cylinder the rotor

is selecting.

- Turn the engine counterclockwise until the TDC mark on the pulley

is lined up with the mark on the case. The rotor will now be pointing

to the spark plug for either cylinder 1 (right front) or cylinder 3

(left front). The cylinder that would be firing will have both valves

closed, so the valves can be adjusted.

- Check valve clearance with a feeler gauge. Error on the high side by .001 on these adjustments. Too tight burns valves. Too loose is just noisy.

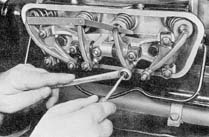

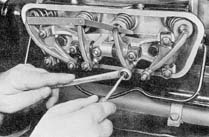

- Loosen hex lock nut.

- Adjust the clearance by turning the adjusting screw with a

screwdriver, holding the nut with a box wrench, and checking with a

feeler gauge. With a bit of practice you can tighten the screw till

resistance is felt. This is too tight and you will need to back off a

bit. The feeler guage should just be freed enough to slide out.

- Hold the adjusting screw firmly in place and tighten lock nut.

- Recheck adjustment.

- Repeat the above on all other cylinders in proper sequence

continuing to turn the engine pulley counterclockwise. TDC for each

cylinder will occur after the crank has rotated 180 degrees.

- Mount rocker box cover.

- Start engine and check both covers for possible oil leaks.

Notes:

- Use a large crescent wrench on the 30 mm crankshaft pulley nut to turn the engine.

- Get a spare set of valve cover gaskets to be sure you have a way to re-seal if the old ones leak.

|