Engine Lubrication System

Oil Circuit Diagrams

|

Oil Circuit in a Cold Engine

|

|

Oil Circuit at Operating Temperature

|

Oil Strainer

Removal

| Remove and replace the Oil Strainer

- 1. Remove hex nuts from oil strainer cover.

- 2. Remove oil strainer cover.

- 3. Remove oil strainer and gaskets.

|

Install

Installation is accomplished in reversed order of the above by noting

the following points:

- Check oil suction tube for proper positioning.

- Clean oil strainer and remove gasket remnants.

- Use new gaskets on both sides of the oil strainer.

- Insert oil strainer making sure that the orifice in the strainer has a close fit around the oil suction tube.

- Remove gasket remnants from the oil strainer cover. Straighten the cover if it is warped or bent, otherwise a good oil seal cannot be expected.

- Clean magnetic filtering element.

- Do not over tighten the hex retaining nuts, especially when using thicker gaskets, since this may warp the cover.

Note:

A magnetic oil filtering element has been included in the oil strainer

cover to provide for a better filtering of the oil. The element is

situated in the center of the oil strainer cover with the oil suction

tube located within it. The oil first passes through the oil screen

and then flows through the magnetic filtering element.

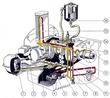

| Magnetic Oil Filter

- Crankcase

- Oil strainer

- Magnetic filter

- Oil suction tube

- Stud

- Oil strainer cover

- Disc

- Rivet

- Gasket

|

Pressure Relief Valve

Special Tools: P 74 Socket attachment

General

The pressure relief valve is located in the crankcase and governs

engine oil pressure.

When encountering malfunctions in the engine lubrication system, and

always in cases of leaks in the oil cooler, check the pressure relief

valve for proper functioning.

The bypass circuit valve is located in the timing gear cover and

ensures immediate lubrication of engine bearings and other points when

the engine is started.

Functional Description of the Bypass Valve:

The purpose of the bypass valve in the timing gear cover is to provide

instant lubrication for points in the engine, by bypassing the oil

cooler, when the engine is started.

| - 1 Oil gallery to oil cooler

- 2 Oil gallery from oil pump

- 3 Oil gallery to lubricating points by bypassing the oil cooler

- 4 Opening for counter-pressure oil line.

|

| When the engine is not running, the valve (plunger) closes the passage

to the lubricating points. As soon as the engine begins to run, the

oil pump sucks oil from the oil sump in the crankcase and forces it to

the bypass valve. The bypass valve is then forced down, under the

pressure of the oil, and opens the oil gallery to the lubricating

points by bypassing the oil cooler.

|

| As soon as the oil pressure has built up, some of the oil flows

through the counter-pressure line to the cavity under the valve

plunger equally counteracting the pressure exerted by the oil from

above, permitting the mechanical spring to expand and, thus, push the

valve plunger up and close the oil gallery of the direct lubricating

circuit. This forces the oil to flow through the oil cooler before it

can reach the lubrication points within the engine.

|

Removal

| 1. Remove cap screw with tool P 74.

|

| 2. Withdraw spring and valve plunger; if plunger is stuck, it can be

removed with an M 10 thread tap.

|

Installation

Installation is accomplished in reversed order of the above by noting

the following points:

- Inspect valve plunger and plunger bore in housing for traces of

seizure (scratches, etc.). Carefully smoothen the surfaces, replace if

necessary.

- Check mechanical spring

Pressure Relief Valve and Bypass Valve Spring

Free length............ 66 mm (2.6in)

Wire diameter......... 1.4 mm (.055in)

Tension at 49 mm(1.93in).....4.7 kp (10.3 lbs) +/- 7%

- Install new gasket washer.

- Insert the piston so that its hollow end faces towards the cap screw.

- To prevent scratching the bore in the housing, make sure that the

spring end does not ride in the plunger bore in housing.

Oil Cooler

Removal

| - 1. Remove air blower housing (4 En).

- 2. Unscrew oil cooler retaining nuts with a box wrench. ..

|

| - 3. Remove oil cooler and gaskets.

|

Installation

Installation is accomplished in reversed order of the above by noting

the following points:

- Check oil cooler for leaks and proper tightness of retaining nuts

(test pressure is 10 atm-147 psi).

- If oil cooler is leaking, check pressure relief valve.

- Use new gaskets.

Oil Pump

Remove

| - Remove engine rear shield and intermediate shield between the air ducts.

- Remove crankshaft pulley.

- Remove crankshaft pulleys shield,

- Remove oil pump cover.

- Remove oil pump gears.

|

Installation

Follow reversed order

- Inspect oil pump housing, especially gear seating areas, for

wear. Wear within the housing will result in decreased oil pressure.

- Inspect pump gears for wear. Gear flank clearance should be O.03 -

O.O5 mm (.001 - .003in.). Axial play of gears in the housing, with

gasket but without preload, is 0.035 - O.10 mm (.0014 - 0039in.). Wear

limit 0.20 mm (. 0079in).

- Check shaft of driven gear for firm seating in the housing.

- Check sealing surface for oil pump cover (a t crankcase) for cleanliness.

- Place a straight edge across the face of the pump gears. Using a

feeler gauge, measure clearance between the cover mounting flange in

housing and face of gears, which should be 0.06- 0.l28 mm

(. 0024 - .0050in).

- Use a new,- genuine gasket (0. 20mm = . OO8in) without applying

gasket paste. Gasket thickness in excess of specification will result

in decreased oil pressure.

Bypass Oil Filter Cartridge

Bypass oil filter cartridges used in Porsche cars cannot be cleaned

and have to be replaced when contaminated (normal replacement after

every 10,000 km or 6,000 miles).

| - Unscrew filter cover retaining bolt.

- Withdraw filter cover.

- Withdraw filter cartridge with a slight turn.

- Remove oil from filter housing (use a suction pump).

- Clean filter housing interior (do not use shredded rags).

- Insert new cartridge by turning it slightly.

- Insert new gasket into housing cover, properly position the cover on

the housing. depress, and tighten securely.

- Check engine oil level.

- Allow engine to idle for a few moments.

- Check for oil leaks in filter housing body and oil line connections.

- Recheck engine oil level.

- Replenish engine oil to the top mark on the oil dipstick (use

premium. grade HD oil).

|

Last modified: Mon, 17 Jan 2005

Links

|