Inspecting Clutch Assembly

Inspection

The Fichtel-Sachs MX 200 K clutch has been designed without provision

for repair or overhaul. The clutch inspection is, therefore, limited

to a thorough visual examination of the component parts.

| 1. Clean the clutch.

2. Check diaphragm spring segments for wear in the throwout bearing

contact area. Groove formation up to a depth of O. 3mm (0.012 in) may

be disregarded.

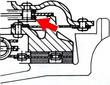

3. Check pressure plate contact surface for cracks, scorching, or

wear. Pressure plates warped inward up to 0,3 mm (0.012 in) (see

illustration) are still serviceable.

|

| 4. Check attachment points of diaphragm spring and spring housing for

cracks. Check rivets for firm seating. Clutch assemblies with damaged

or loose rivet connections must be replaced.

|

| 5. The diaphragm spring is riveted to the spring housing with two wire

ring spacers in between.

Clutch assemblies. showing visible wear at the rivet heads or at the

wire ring spacers should be replaced.

6. Lightly coat the diaphragm spring seat at the wire ring seating

area with MoS2 paste prior to installation.

|

Last modified: Mon, 17 Jan 2005

Links

|