Removing and Installing Pistons

Special Tools:

P 1a Electric piston heater P 2 Piston pin mandrel

General:

| The piston pins are arranged in the pistons off the center and it is,

therefore, important to correctly install the pistons in the

engine. The piston top bears an arrow mark. When installed, the piston

must be so oriented that the arrow points in the direction of vehicle

travel, i. e., towards the flywheel.

|

| Owing to the off-centered piston pin, the connecting rod shifts its

direction of attack, and so does the piston its tangential angle in

relation to the cylinder wall prior to reaching the top dead center

(TDC). Since in this position the combustion has not yet begun, the

prevailing side forces are still small. which permits the piston to

shift onto the opposite cylinder wall softly rather than with a

slamming impact. As a result, piston slap noise occuring at time of

the pressure point shift is kept at a minimum, especially when the

piston to cylinder wall clearance is greater than normal.

|

Removal

| 1. Remove cylinders (36 En).

2. Mark pistons to ensure reassembly in original position and

location.

|

| 3. Remove piston pin retainers making sure they don't fall into

crankcase.

4. Heat pistons to approx 80 deg C (175 deg F) using electric piston

heater.

|

| 5. Using the piston pin mandrel, drive piston pins out and remove

pistons.

6. Remove piston rings (if necessary) using a piston ring expander. To

avoid breaking or bending the piston rings, expane! these as little as

possible, keeping rings close to the piston body.

|

Installation

Install pistons in reversed order of the above by noting the following

points:

| 1. Connecting rods must be in proper alignment.

2. Clean pistons. Remove carbon deposits from piston top and piston

ring grooves without scratching the base metal. Signs of uneven

contact or carbon deposits on one side of the piston may indicate poor

connecting rod alignment.

3. Check piston rings for proper condition, ring gap, and ring groove

clearance. If not as specified, replace piston rings or pistons, as

required.

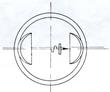

4. Measure pistons. Size designation is stamped into each piston

top. Measurements are accomplished as shown in the illustration

(perpendicular to piston pin axis).

Piston size groups are shown in tables under 40 En. Piston clearance

at installation is 0.02 mm (0.0008 in). If the measurement of the

piston and cylinder reveals a clearance approaching the wear limit,

the piston and cylinder should be replaced with a set falling into the

same size group. If the mating cylinder of a damaged piston does not

show traces of wear or damage, it may be possible to replace the

piston alone with one falling into the appropriate size (letter)

group.

|

| 5. Fit compression rings and oil scraper.

6. Check piston ring gap. This is done by inserting the ring into the

cylinder and pushing it down, somewhat. with a piston. then measuring

gap with a feeler gauge.

Applicable to all rings:

Ring gap 0.3 - 0.45 mm (0.012 - 0.018 in). Stagger piston ring gaps so

that they are approx. 120 deg apart.

Piston ring side clearance is specified in the Table of Tolerances and

Wear Limits (page E 95).

Piston rings must be installed with a ring expander to prevent piston

damage or ring breakage.

Piston rings must be installed in the piston so that the "TOP" marking

on the ring faces up, i. e., towards the piston top.

|

| 7. Insert piston pin retainer on the flywheel side first.

8. Inspect and install piston pin. The piston pin is held in the

piston through interference fit. If the piston pin can be pushed into

the cold piston by hand, use a pin of larger diameter. A color code

marking inside the piston on the piston pin boss indicates the proper

size of the piston pin, as follows:

white - 21. 997 -22. 000 mm

blue - 22.000-22,003 mm

Piston pin clearance in the connecting rod bushing is O. 020 - 0.036

mm (0.OOO8 in to 0.0014 in). If the clearance a pproaches the wear

limit of 0.050 mm (0.002 in), fit a new piston pin into a new

connecting rod bushing.

Install the cold, oiled piston pin in the piston which has been heated

to 80 deg C (175 deg F) through immersion in hot oil or application of

the e1ectric piston heater, in which condition the pin should slide

into the piston under light pressure; the pin should be pushed

through, to the pin retainer, in one continued move.

9. Install second pin retainer. The pin retainers must fit well in

their groove within the piston pin boss.

|

Last modified: Mon, 17 Jan 2005

Links

|