Checking and Reconditioning Valve Seats

Special Tools

- P 11 Valve seat cutter handle with 10 mm dia. cutter guide

- P 12 Eight-piece valve seat cutter set.

Checking

- Check valve guides for firm seating in the cylinder head.

- Check valve seating using machinists blue.

- Inspect valve seat surface. If the valve does not seat on the whole

seat surface, lightly rework the seat with a cutter.

- Valve seating may be checked with the valves installed in the

cylinder head by pouring some gasoline into the respective port.

Reworking-Valve Seats

|

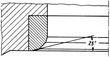

Valve seat width

Intake 1.25 +/- 0.15 mm (0.050 +/- 0.006 in.)

Exhaust 1.55 +/- O. 15 mm (0.061 +/- 0.006 in.).

Valve seats showing traces of wear or pitting may be refaced providing

that the permissible width of the 45 deg. seat can be maintained, and the

25 deg. bevel in the outer circumference does not exceed the outer

diameter of the valve seat insert. If this is not possible, the

cylinder head must be replaced. It is not p~sible to replace the yalve

seat inserts with the equipment at hand in normal workshops.

|

Work Procedure

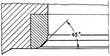

| 1. 45 deg seat cut:

The 45 deg cut must be performed with particular care to produce a smooth

surface free of chatter marks. It is very important to apply pressure

from directly above. Removal of base metal must be held at a minimum

so as not to render the valve seat insert prematurely unusable. The

cutting procedure should be discontinued as soon as the cutter has

cleaned the entire seat area,

|

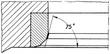

| 2. 75 deg bevel cut: Lightly bevel the lower edge of the valve seat using

the 75 deg. cutter.

|

| 3. 25 deg bevel cut: Using the 25 deg. cutter, bevel the upper edge of the

seat until the specified seat width is obtained.

|

Last modified: Mon, 17 Jan 2005

Links

|