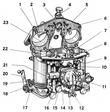

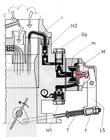

Description of the Solex 40 P II - 4 Carburetor

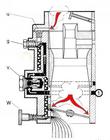

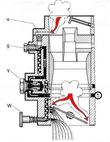

Parts Diagram

|

This diagram is for the early cars.

|

|

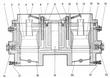

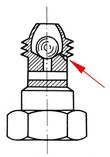

Later cars.

|

General

| The Type 912 Porsche is equipped with two SOLEX 40 P II - 4

double-throat downdraft carburetors. The induction throats are 40 mm

(1.575in) in diameter. Since the carburetors are located very close to

the combustion chambers, cold starting enrichment devices are not

needed.

|

Description

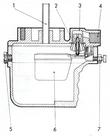

| The carburetor basically consists of the main body and cover, with a

gasket separating the two. The main body contains two induction

barrels, each having an independent idle and power metering

system. The throttle shaft, which passes through both barrels,

controls both throttle valves and carries a throttle return stop and

throttle arm.

|

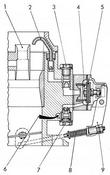

| The accelerating pump located on the broad side of the carburetor is

actuated through an adjustable rod and feeds fuel to both induction

throats.

|

| The float chamber is located between both induction throats. The

fuel level in the float chamber is regulated through the buoyancy

of the float, that is, the float tang opens or closes the float needle

valve. The float level may be adjusted by means of an externally

located screw which adjusts the height of the intermediate swivel

joint. This provision makes it possible to easily adjust the float

level for the particular grade of fuel used. The fuel level may be

checked by removing the plug from the inspection port.

The carburetor cover accommodates the fuel inlet, float chamber vent,

and float needle valve (the latter is accessible from within). In

addition, two power enrichment nozzles are press-fit into the cover.

|

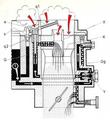

Idle Metering

| The fuel enters through the idle metering jet (g) and mixes with air

entering through the idle air bleed (u) forming an emulsion. The

emulsion flows to four small discharge ports located near the throttle

valve. The amount of emulsion dispensed through the lowest port is

controlled by the idle mixture screw (W). The emulsion dispensed into

the induction throat through the idle mixture port combines with

induction air which is passing through the partly open throttle valve

and atomizes into idle mixture.

The idle mixture can be leaned out by turning the adjustment screw in,

and enriched by turning it out: both screws should be set

approximately same.

The idle speed adjustment controls the engine idle rpm, i. e.. turning

the screw clockwise increases the rpm, and turning it counterclockwise

decreases rpm.

The idle system employed in this carburetor is an independent system

since it draws the fuel from a point before the main jet carrier

(Y). As a result, negative pressures prevailing in the induction

throat have a continuous effect on the idle metering system and a

certain amount of the idle mixture is fed into the induction throats

at normal power settings as well.

|

Intermediate Metering

| The three discharge ports located above the idle mixture discharge

port provide progressive metering at intermediate throttle openings

between idling and power. The lowest port, located at the throttle

valve level, feeds idle mixture when the throttle is set for idling,

while the two upper ports begin to feed the mixture as the throttle

begins to open. This metering provision ensures smooth transition from

idle speeds to power settings.

|

Power Metering

| The fuel flows through the main jet carrier (Y) and the main jet (Gg)

into a well which contains the emulsion tube (s) and, directly above

it, the air correction jet (a). Vacuum in the induction throat draws

the fuel into the preatomizer (X) where it mixes with air and

continues to the venturi (K) where it is fully atomized into the

combustion mixture. As the vacuum in the induction throat increases,

the fuel level in the emulsion tube well decreases and air enters

through the air correction jet, mixing with the fuel through orifices

in the emulsion tube and effecting a derichment of the fuel air

mixture.

|

| As long as the engine is operating in the mid-rpm range under partial

or full throttle load, only the main metering system supplies the

fuel. However, as the air velocity in. the induction throat increases

with increasing rpm, the vacuum effect in the throat becomes so

intense that it begins to draw supplemental fuel from the power

enrichment nozzle (q1); the power enrichment system consists of the

discharge nozzle ([1) and the metering jet (q2) and draws fuel

directly from the float chamber. The enrichment system comes into

action when the engine is running under full throttle at high rpm.

The main metering system together with its supplemental enrichment

system ensures a well balanced and metered fuel! air mixture required

for combustion, realizing the desired fuel economy and, yet, maximum

power output on demand.

|

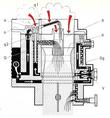

Acceleration

| A mechanically actuated diaphragm-type accelerating pump is

employed. The pump receives fuel directly from the float chamber. When

the pump is at rest,. the diaphragm (M) is kept outwards by the

diaphragm spring (m). A s the throttle valve opens, actuating motion

is transmitted to the pump by the pump rod (T) and pump lever (L5),

pushing the diaphragm inward against the fuel and forcing it to pass

through the pump jet (Gp) and the calibrated injection nozzle (i) into

the venturi, enriching the fuel/ air mixture and resulting in smooth

engine response at acceleration.

The check valve (Hl), in the pump inlet, prevents the fuel from

backing up into the float chamber; a second check valve (HZ), at the

base of the injection nozzle, prevents air from entering the pump

through the injection nozzle when the pump is on the inlet stroke.

The amount of fuel dispensed by the pump on its pressure stroke at

time of acceleration is predetermined by the length of the pump

stroke; the stroke can be adjusted through the pump adjustment

(t). The pump jet and the calibrated injection nozzle control only the

duration of injection.

|

| The check valve assembly (HI) has a return flow passage measuring

O.36 mm (0.0142 in) in diameter. This port prevents excessive

enrichment of the fuel/ air mixture by fuel dispensed by the fuel pump

during acceleration, that is, depending upon the speed with which the

throttle pedal is depressed, larger or smaller amounts of fuel are

permitted to flow back to the pump.

|

Last modified: Fri, 12 Aug 2005

Links

|