Adjusting Idle Speed

Special Tools:

P 227 Carburetor Synchronizer

Adjustments

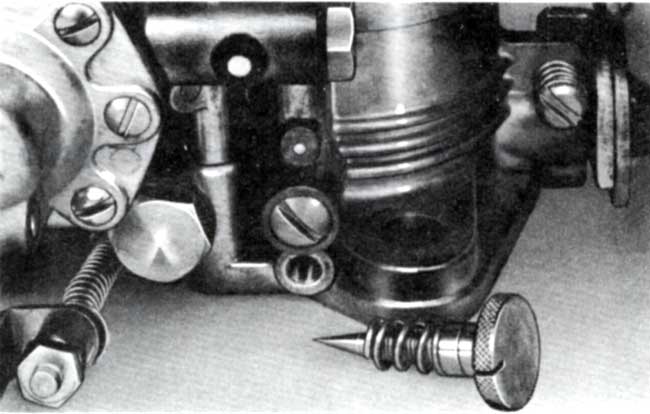

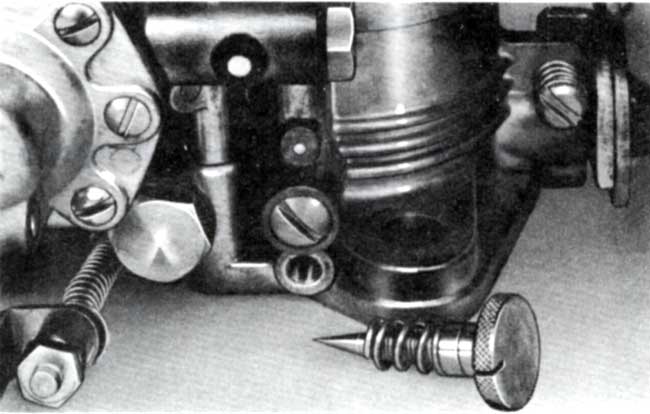

- Remove idle mixture adjusting screws and inspect needle tips for

burrs, grooves, and bends. Install new screws if in doubt,

- Bring engine to normal operating temperature and remove air cleaners.

- Detach throttle rods from throttle arms.

- Uniformly turn idle adjusting screws in until engine idles at about

1,000 rpm.

- Following any convenient sequence turn idle mixture screws fully in

on both carburetors - do not tighten since this can damage the needle

points - then back off 1 1/2 turns. From this position turn the screws

in or out until fastest idling speed is achieved, In no case should

the screws be left in fully turned-in position.

- Adjust idle speed screws until the engine idling rpm drops to 800 - 900.

- Place carburetor synchronizer (P 277) on carburetor throat and

adjust plunger glass to vertical position.

- Turn adjusting disc in synchronizer until plunger moves to about

half-way between two marking rings about midway of the glass tube

length; this accomplished, the synchronizer is set for the particular

engine and no further adjustments should be made with the disc in

the synchronizer.

- Place synchronizer (P 277) onto second throat of the carburetor

assembly; the plunger should move up to same point as during procedure

described above. If the reading is different, the throttle valves are

not in alignment and must be synchronized, which is easily

accomplished by twisting the throttle shaft. Using the synchronizer,

recheck synchronization of both throttle valves by comparing readings

of the synchronizer when placed first on one, then on the other throat.

- Without changing synchronizer adjustment. place synchronizer onto

throats of second carburetor assembly and adjust throttle valve with

idle speed screw so that the plunger in synchronizer moves to same

height as observed during test described in Pt. 9, above readjust

throttle valve if necessary,

- Should it be noted during the adjusting procedure that the idle

speed has changed, readjust idle speed screw settings and recheck

carburetor synchronization with the synchronizer, correct of necessary.

- Reconnect throttle rods to throttle arms.

NOTE ! Adjust carburetor rods so that these can be attached to the

carburetor arms without preload in relation to each other.

- Set idling speed to 1,200 - 1,300 rpm. Using the synchronizer (P

227) recheck synchronization of all throats as described in Pts. 8 and

9. If the gauge does not show equal values in both carburetors,

synchronize these with each other by properly adjusting the carburetor

throttle rods.

- Recheck idle speed.

- Check injection quantity (warm season 0.45 cc from each nozzle on

two pump strokes, 0,65 cc in cold season).

- Check accelerator pedal stop bolt and adjust if necessary. When

the accelerator pedal is depressed against the stop bolt, the

carburetor arm should be clearing the carburetor stop block by about 1

mm (.039 in).

- Install air cleaners with gaskets, tighten retaining screws.

|