Adjusting Injection Quantity

Special Tools:

P 25a Calibrated Vial

Adjustments

- Adjusting idle speed.

- Run engine to fill float chamber with fuel.

- Stop engine, remove both air cleaners.

- Work throttle arm until air bubbles cease to show at the pump

injection nozzle.

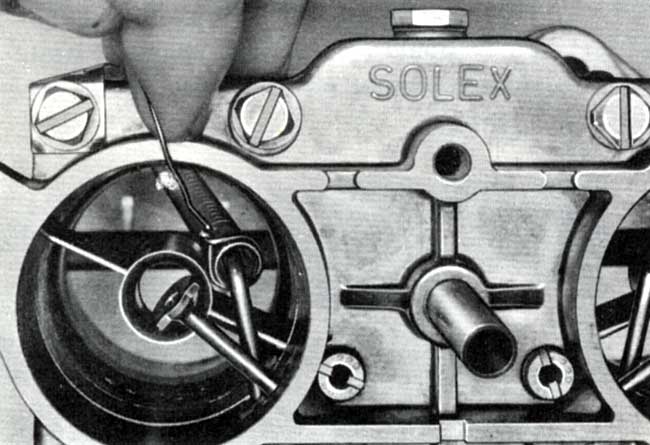

- Hold calibrated vial (P 25a) at the tip of the nozzle and quickly

move throttle arm two times from stop to stop.

- Check injection quantity, empty the calibrated vial, repeat

procedure on the second, injection nozzle.

- Injection quantity from each nozzle on two pump strokes should be

0.45 cc (7.3 minimum) during the warm season, and O. 65 cc (10.6

minimum) during the cold season.

- Check injection quantity in second throat.

- If required, readjust injection quantity by resetting the adjusting

nut on the pump rod. If adjustment should not be possible due to lack

of threads, insert a spacer between the pump arm and the nut.

Note

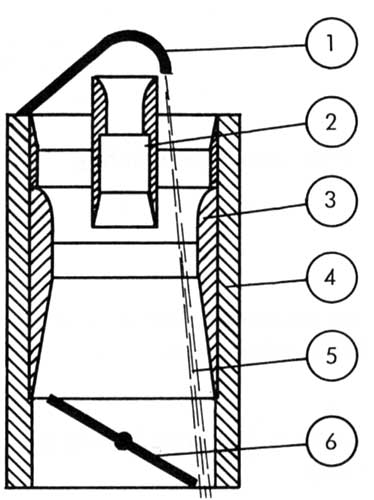

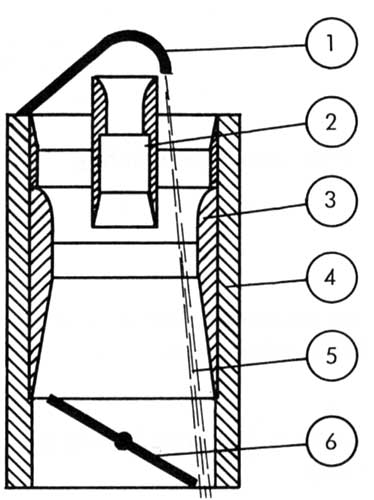

Fuel squirting from the pump nozzle should not strike the pre-atomizer

nor the venturi and must pass through the slit between carburetor wall

and throttle valve,

- Injection nozzle

- Pre-atomizer

- Venturi

- Carburetor body

- Squirting fuel

- Throttle valve

Should it become necessary to bend the injection nozzle, insure that

its tip remains at same height. The pump jet does not affect the

injection quantity. Changes in size of the pump jet affect only the

duration of injection since the jet size controls the flow only in

respect to flow duration. Injection quantity as well as the moment of

injection must be identical in all carburetor throats.

|