Reconditioning Fuel Pump

Disassembly

- Remove cover retaining hex bolt.

- Remove cover and fuel screen.

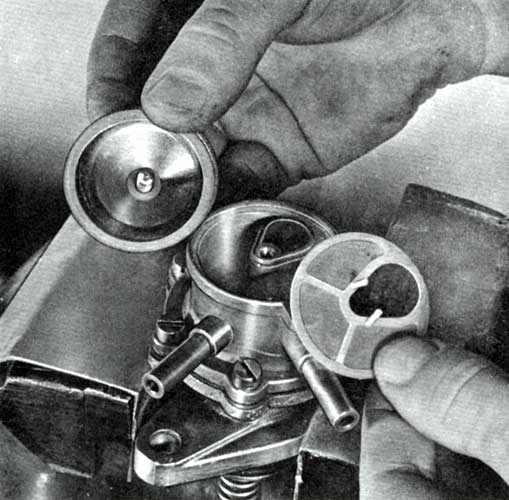

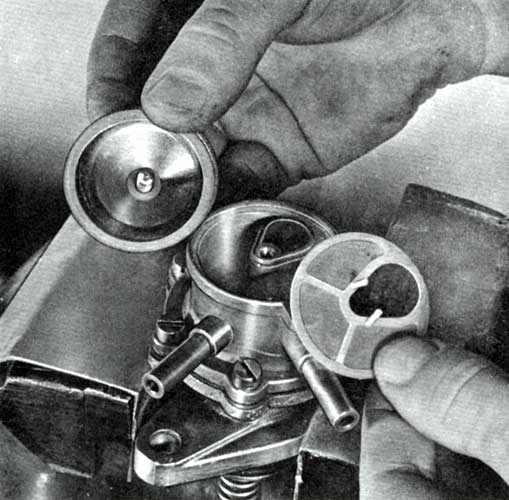

- Remove six fillister screws which secure the upper assembly, withdraw assembly.

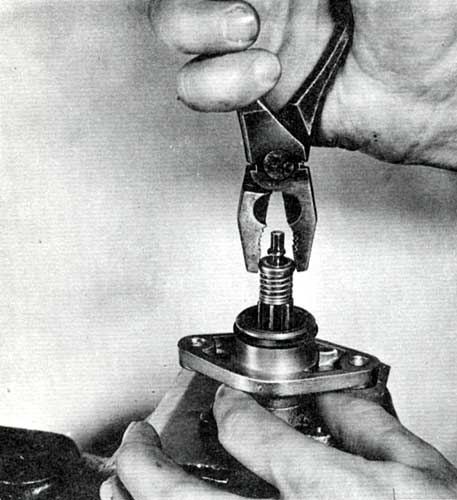

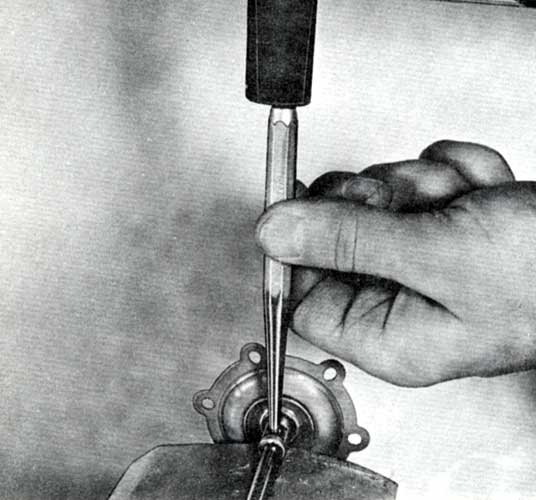

- Rest the lower assembly of pump on the diaphragm supporting disc,

push spring retainer down with pliers, remove lock ring, spring

retainer, and spring.

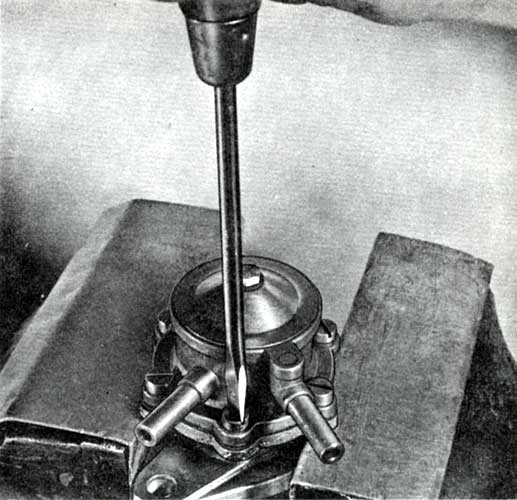

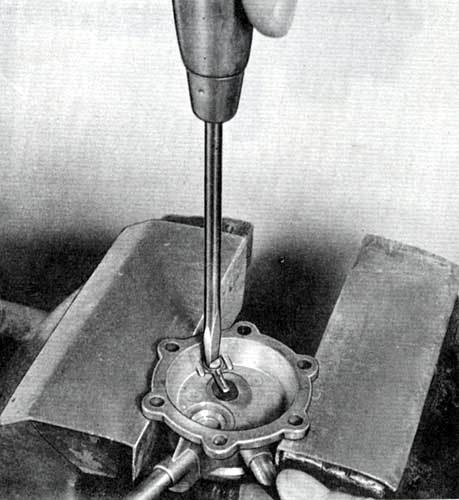

- Withdraw the diaphragm-plunger-spring assembly from lower pump

casting. Ensure that there is no grit around the lock ring groove in

plunger to prevent damaging the oil scraper.

- Remove coupling pin from actuating plunger with a punch, detach

diaphragm from plunger.

- Remove self-threading fillister screw from inlet valve and remove

leaf spring valve and valve limiter (outlet valve cannot be removed).

- Clean pump components with gasoline.

Reassembly

Reassembly is accomplished in reversed order of the above by noting

the following points:

- Check outlet valve in upper assembly for proper functioning.

- Check sealing surfaces of inlet valve.

- Install leaf spring valve and valve limiter, check for proper operation.

- Reconnect diaphragm with plunger with the pin, check free movement

of plunger in diaphragm coupling. Center coupling pin in plunger.

- When mounting pump upper assembly. ensure that the diaphragm is

not creased. Evenly tighten screws in cross-sequence.

- Check gasket at pump cover, replace if necessary.

|